Introduction

In the realm of bulk liquid transportation, ISO tank containers have emerged as an efficient, reliable, and cost-effective solution. These standardized containers facilitate the safe and seamless movement of liquids, gases, and powders across the globe. This article explores what an ISO tank container is, its design and specifications, advantages, and applications.

Definition of an ISO Tank Container

An ISO tank container, commonly referred to as an ISO tank, is a cylindrical, stainless steel container designed to transport bulk liquids, gases, and powders. The term “ISO” stands for the International Organization for Standardization, which sets the container’s specifications to ensure global compatibility and safety. These tanks adhere to ISO 668 standards and are used in various industries such as chemicals, food and beverage, and petroleum.

Design and Structure

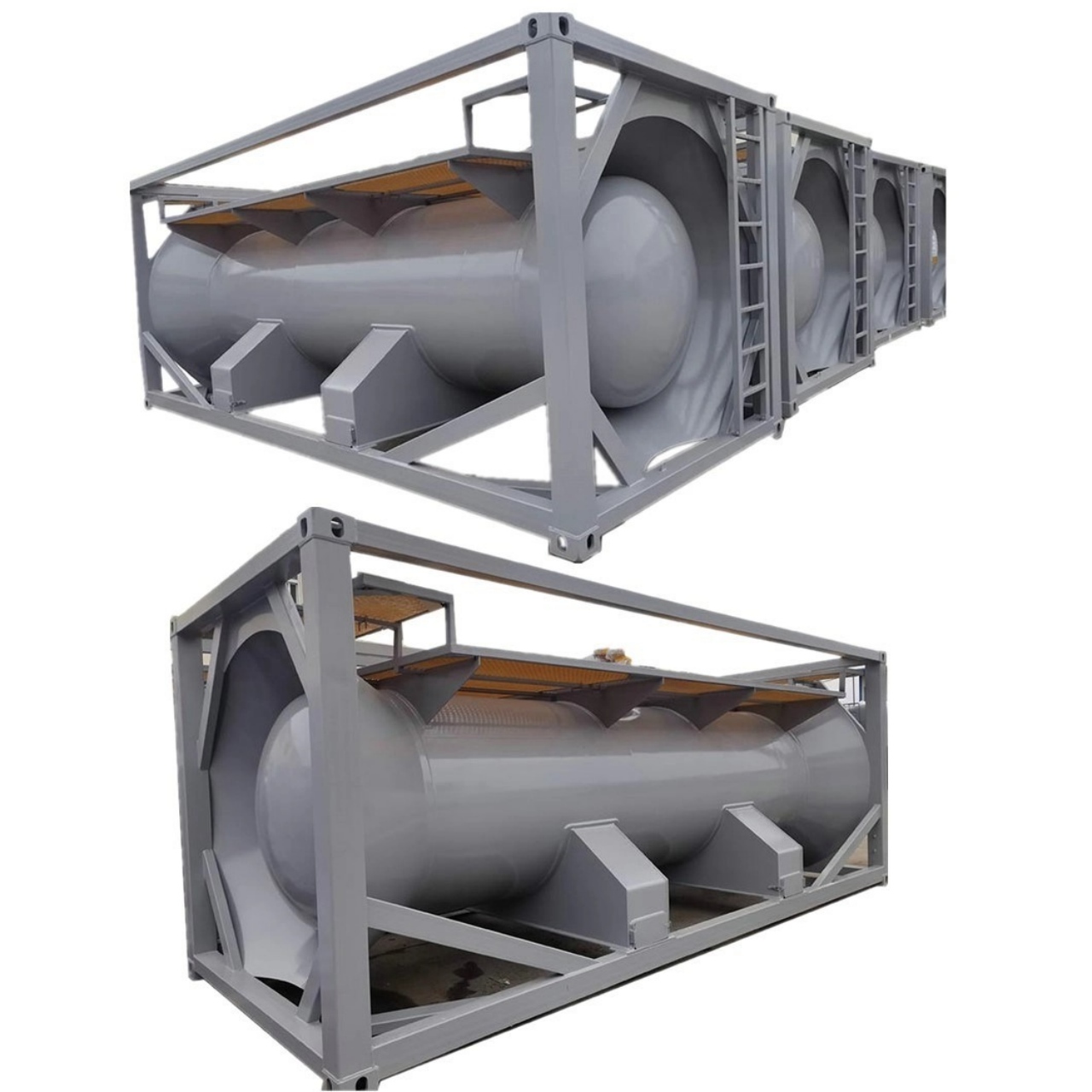

ISO tank containers are constructed with high-quality stainless steel and are typically surrounded by an insulation and protective layer made of polyurethane or aluminum. The tank is mounted within a steel frame, generally measuring 20 feet in length, which aligns with standard intermodal container dimensions. This design allows for easy transportation via road, rail, or sea.

Key components of an ISO tank container include:

- Shell: The cylindrical body is made of corrosion-resistant stainless steel.

- Manway: A hatch on the top of the tank for filling and inspection.

- Valves and Fittings: Various inlet and outlet valves to facilitate the loading and unloading of liquids.

- Safety Features: Pressure relief valves, temperature control mechanisms, and protective coatings.

- Frame: A rectangular steel structure supporting and protecting the tank, allowing for intermodal compatibility.

Types of ISO Tank Containers

ISO tank containers are classified based on the type of cargo they are designed to carry. The most common types include:

- Standard ISO Tank: Used for transporting non-hazardous liquids such as vegetable oils, fruit juices, and pharmaceuticals.

- Chemical ISO Tank: Designed for carrying hazardous chemicals, featuring enhanced safety mechanisms like specialized linings and pressure relief systems.

- Food-Grade ISO Tank: Constructed to meet strict sanitary standards for the transportation of consumable liquids like milk, wine, and edible oils.

- Gas ISO Tank: Engineered for compressed and liquefied gases, requiring reinforced pressure-resistant designs.

- Bitumen and Asphalt ISO Tank: Built to handle high-temperature materials with insulation and heating capabilities.

- Swap Body Tank: Larger capacity tanks primarily used in Europe for road and rail transport.

Advantages of ISO Tank Containers

ISO tank containers offer several benefits over traditional bulk transportation methods such as drums, barrels, and flexitanks. Some of these advantages include:

1. Cost-Effectiveness

ISO tanks provide a higher payload capacity compared to drums or intermediate bulk containers (IBCs), reducing per-unit transportation costs. Additionally, they minimize the need for extensive packaging materials.

2. Intermodal Efficiency

These containers are designed for seamless transfer between trucks, trains, and ships, reducing handling time and associated costs.

3. Safety and Security

ISO tanks are built with robust safety features, including pressure relief valves, leak-proof seals, and reinforced structures, making them safer for hazardous and non-hazardous materials.

4. Environmental Benefits

Reusable and easy to clean, ISO tank containers contribute to reducing waste associated with single-use packaging like drums and barrels.

5. Durability and Longevity

With proper maintenance, ISO tanks can last 20 years or more, making them a long-term investment for logistics companies.

Applications of ISO Tank Containers

ISO tank containers are widely used in multiple industries, including:

1. Chemical Industry

They transport hazardous and non-hazardous chemicals such as acids, solvents, and industrial lubricants.

2. Food and Beverage Industry

Food-grade ISO tanks are used for transporting bulk liquids like milk, beer, and vegetable oils while maintaining strict hygiene standards.

3. Petroleum and Gas Industry

LPG, LNG, and other petroleum derivatives are transported in specially designed gas ISO tanks.

4. Pharmaceutical Industry

Pharmaceutical companies use ISO tanks for sterile and temperature-controlled transport of liquid medicines and medical-grade solvents.

5. Construction Industry

Bitumen and asphalt ISO tanks are used for the transport of high-temperature road construction materials.

Regulations and Safety Standards

ISO tank containers must comply with international safety regulations, including:

- International Maritime Dangerous Goods (IMDG) Code: Regulates the safe transport of hazardous materials via sea.

- ADR (Agreement concerning the International Carriage of Dangerous Goods by Road): Governs road transportation in Europe.

- RID (Regulations concerning the International Carriage of Dangerous Goods by Rail): Covers rail transport safety.

- US DOT (Department of Transportation) Standards: Ensures compliance with U.S. safety laws.

Additionally, ISO tanks undergo rigorous inspections and certifications, including:

- Five-year periodic inspections for integrity and safety.

- Leak testing to prevent spillage risks.

- Pressure tests to ensure compliance with industry standards.

Maintenance and Cleaning

Proper maintenance and cleaning are essential for extending the lifespan of an ISO tank and ensuring cargo purity. Cleaning methods depend on the transported substance and may include:

- Steam Cleaning: Used for food-grade tanks and chemical tanks to remove residues.

- Chemical Cleaning: Utilized for highly viscous or hazardous substances.

- Automated Tank Cleaning Systems: Offer efficient and eco-friendly cleaning solutions.

ISO tank owners and operators must maintain detailed records of cleaning processes to comply with international regulations and quality control standards.

Conclusion

ISO tank containers have revolutionized bulk liquid, gas, and powder transportation by offering a safe, cost-effective, and environmentally friendly alternative to traditional shipping methods. With their standardized design, robust safety features, and intermodal capabilities, ISO tanks remain a vital asset for industries worldwide. As global trade continues to grow, the demand for ISO tanks is expected to rise, further cementing their role in the logistics and transportation sector.