Transporting hazardous liquids such as fuel and industrial chemicals requires specialized equipment that can ensure safety, efficiency, and durability. In this context, aluminum tank trucks have become a favored solution due to their lightweight construction, corrosion resistance, and reduced maintenance demands. These tankers are essential for industries that rely on bulk transport of liquids and gases, ranging from petroleum distribution to agricultural and chemical supply chains.

This article explores the technical advantages, key applications, and design considerations of aluminum tank trucks, focusing on their use in transporting fuels and chemicals.

1. The Case for Aluminum in Tanker Construction

The traditional materials used in tank truck manufacturing include carbon steel and stainless steel. While these materials offer strength and durability, they come with significant downsides—mainly excessive weight and vulnerability to corrosion in certain environments.

Aluminum, on the other hand, offers a highly attractive set of properties:

- Lightweight: Aluminum is nearly 3 times lighter than steel, reducing the overall curb weight of the truck and allowing for increased payload capacity.

- Corrosion-resistant: Unlike steel, aluminum forms a natural oxide layer when exposed to air, making it naturally resistant to rust and many chemicals.

- Thermal conductivity: This metal provides good thermal dispersion, which can be important for temperature-sensitive fluids.

- Recyclability: Aluminum is 100% recyclable without loss of properties, aligning with green and sustainable transportation goals.

2. Key Benefits of Aluminum Tank Trucks

A. Higher Payload Efficiency

By using aluminum instead of steel, manufacturers reduce the tare weight of tank trucks by several hundred kilograms. This directly translates into greater payload efficiency, meaning more product can be hauled per trip. For operators, this improves fuel economy and operational cost-effectiveness.

B. Rust-Free Operation

Aluminum’s resistance to corrosion is particularly advantageous in environments where trucks are exposed to moisture, road salts, or chemical vapors. This makes aluminum tankers a preferred choice for chemical haulers, especially when carrying substances like caustic soda, ethanol, methanol, or urea-based solutions.

C. Lower Maintenance Costs

Steel tankers often require coatings, linings, or galvanization to resist corrosion. These protective layers degrade over time and require costly reapplication. Aluminum eliminates much of this need, reducing downtime and maintenance costs significantly.

D. Enhanced Lifespan

Thanks to their resistance to environmental and chemical degradation, aluminum tank trucks can remain in service longer than their steel counterparts. This durability improves asset ROI (return on investment) for fleet operators.

3. Applications in Fuel and Chemical Transport

Aluminum tank trucks are ideally suited for:

A. Fuel Transport (Diesel, Gasoline, Kerosene)

Aluminum is widely used in fuel tankers due to its non-sparking nature and resistance to petrochemical corrosion. These tankers are commonly seen at gas stations and bulk fuel distribution centers.

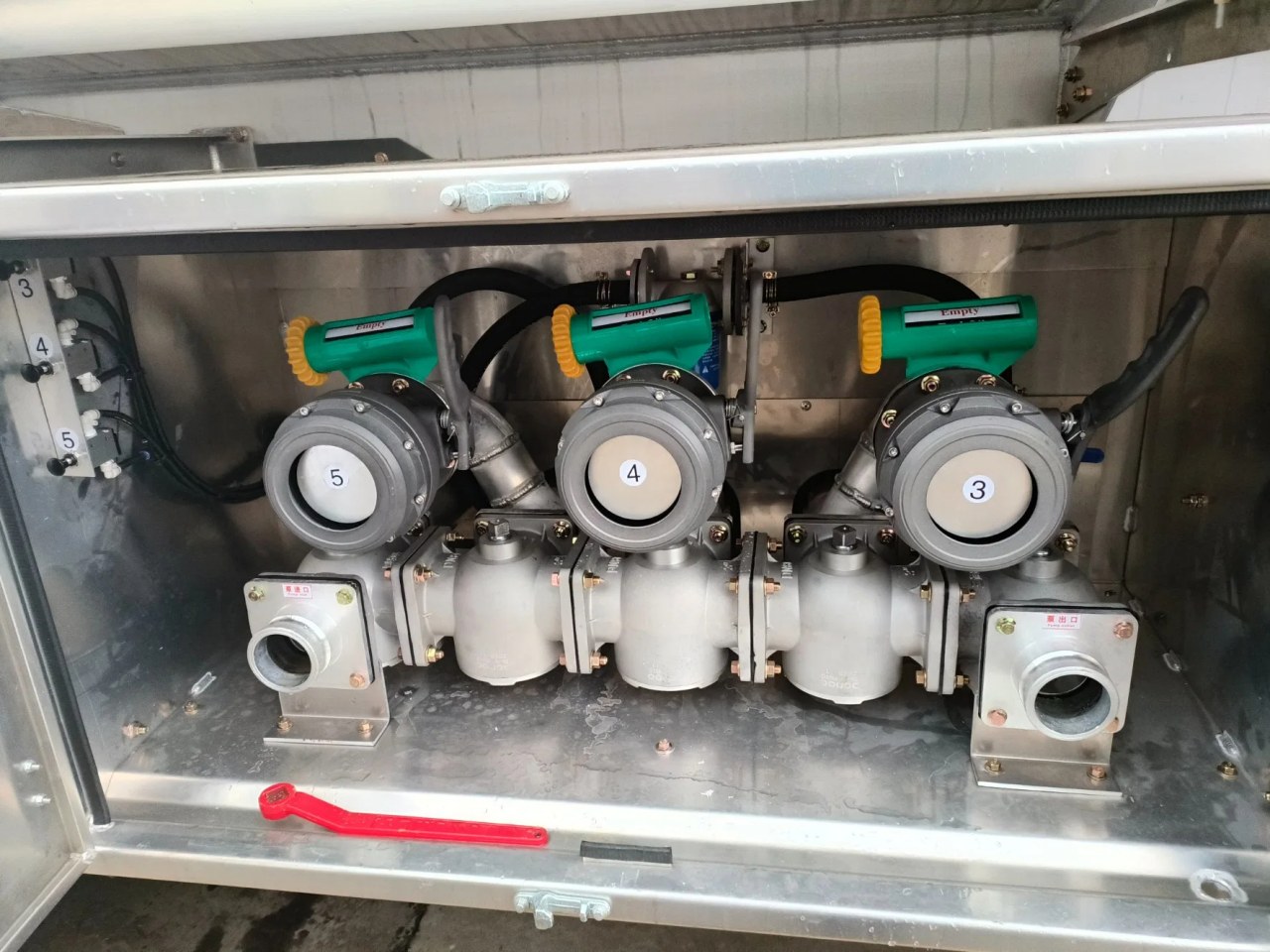

- Compartmentalized designs allow for the transport of multiple fuel types in a single trip.

- Bottom-loading and vapor recovery systems can be seamlessly integrated.

B. Chemical Transport (Solvents, Alcohols, Acids)

While aluminum is not suitable for all chemicals (e.g., strong acids like hydrochloric or sulfuric acid), it performs exceptionally well with alcohol-based chemicals, organic solvents, and many bases. For example:

- Ethanol and methanol transport is frequently carried out in aluminum tankers.

- Aqueous ammonia and caustic soda solutions can be transported with appropriate internal coatings or anodizing.

4. Design Features and Innovations

Modern aluminum tank trucks include advanced engineering features to enhance safety, loading efficiency, and compliance with global transport regulations.

A. Multi-Compartment Tanks

These tanks are divided into several sealed compartments to allow the transportation of multiple liquids at once. This feature improves route efficiency and reduces the need for return trips.

B. Insulation and Heating Options

For transporting temperature-sensitive chemicals, aluminum tanks can be equipped with insulated jackets or heating coils (steam or electric). This is critical in colder regions to prevent product solidification.

C. Pressure Relief Systems

Aluminum tanks used for volatile or reactive chemicals are fitted with pressure relief valves, emergency vents, and rupture discs. These mechanisms prevent tank over-pressurization during accidents or extreme temperature changes.

D. Anti-Spill and Overfill Systems

These systems are mandatory for fuel distribution. Sensors and shut-off mechanisms reduce the risk of environmental contamination and comply with EPA and ADR regulations.

5. Regulatory Compliance and Safety Standards

Manufacturers of aluminum tank trucks must comply with a range of international and local standards, such as:

- DOT 406 / 407 / 412 (USA): About the transport of flammable and corrosive liquids.

- ADR (Europe): Agreement concerning the International Carriage of Dangerous Goods by Road.

- UN Model Regulations: For cross-border chemical transport.

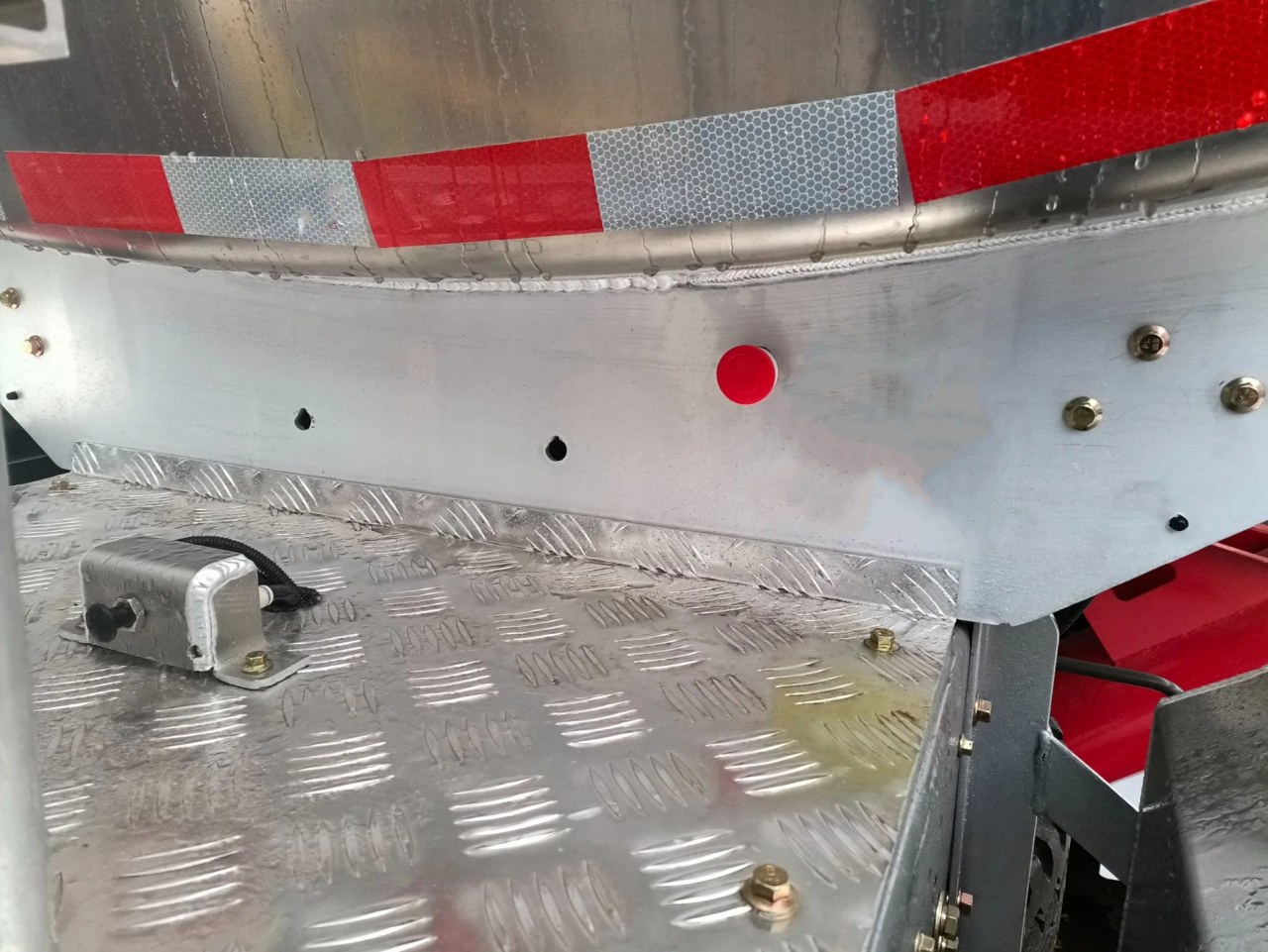

Aluminum tankers are subject to periodic pressure testing, leak checks, and structural inspections to ensure continued compliance and roadworthiness.

6. Limitations and Considerations

While aluminum is advantageous in many ways, it does come with certain limitations:

- Not suitable for all chemicals: Strong oxidizers and mineral acids can corrode aluminum. In these cases, stainless steel or lined carbon steel may be preferred.

- Lower impact resistance: Compared to steel, aluminum has lower tensile strength, which may affect its performance in rough terrain or off-road applications.

- Cost: Aluminum is generally more expensive as a raw material. However, the lifecycle cost—including maintenance and fuel efficiency—often offsets the upfront premium.

7. Market Trends and Future Outlook

With increasing regulatory focus on fuel efficiency, emission reduction, and sustainability, the demand for aluminum tank trucks is growing globally. Countries in North America, Europe, and parts of Asia-Pacific are experiencing a steady rise in the deployment of aluminum-bodied transport vehicles for petrochemical and hazardous materials.

Innovations such as modular tank designs, hybrid material integration, and autonomous safety features are set to further improve the performance and safety of aluminum tank trucks in the coming years.

Conclusion

Aluminum tank trucks represent a powerful combination of efficiency, durability, and environmental compatibility for the transport of fuels and many industrial chemicals. Their corrosion resistance, lightweight nature, and long operational life make them a smart investment for fleet operators looking to optimize performance and reduce total ownership costs.

As industries continue to demand safer and more sustainable liquid transport solutions, the role of aluminum tankers will only become more prominent in the global logistics landscape.