In today’s globalized economy, the seamless and secure movement of liquids and gases across borders is critical to a wide range of industries—from petrochemicals and food processing to pharmaceuticals and energy. One of the most efficient, standardized, and versatile solutions for this task is the intermodal ISO tank container. These tank containers, designed according to strict international standards, have become the backbone of bulk liquid and gas transportation around the world. With their intermodal capability—meaning they can be transported by road, rail, or sea without the need for transloading—ISO tank containers offer unmatched flexibility, safety, and cost efficiency.

What Are ISO Tank Containers?

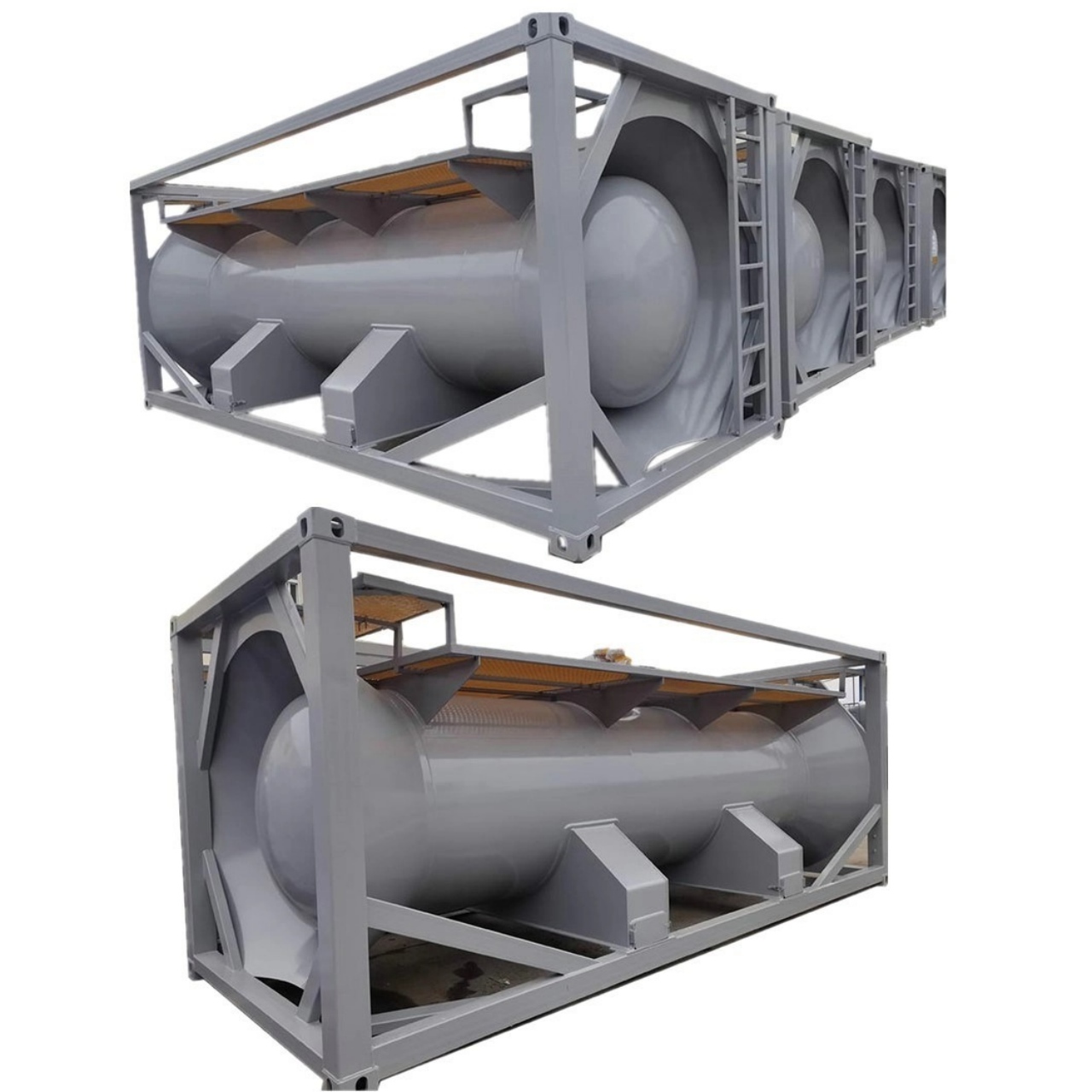

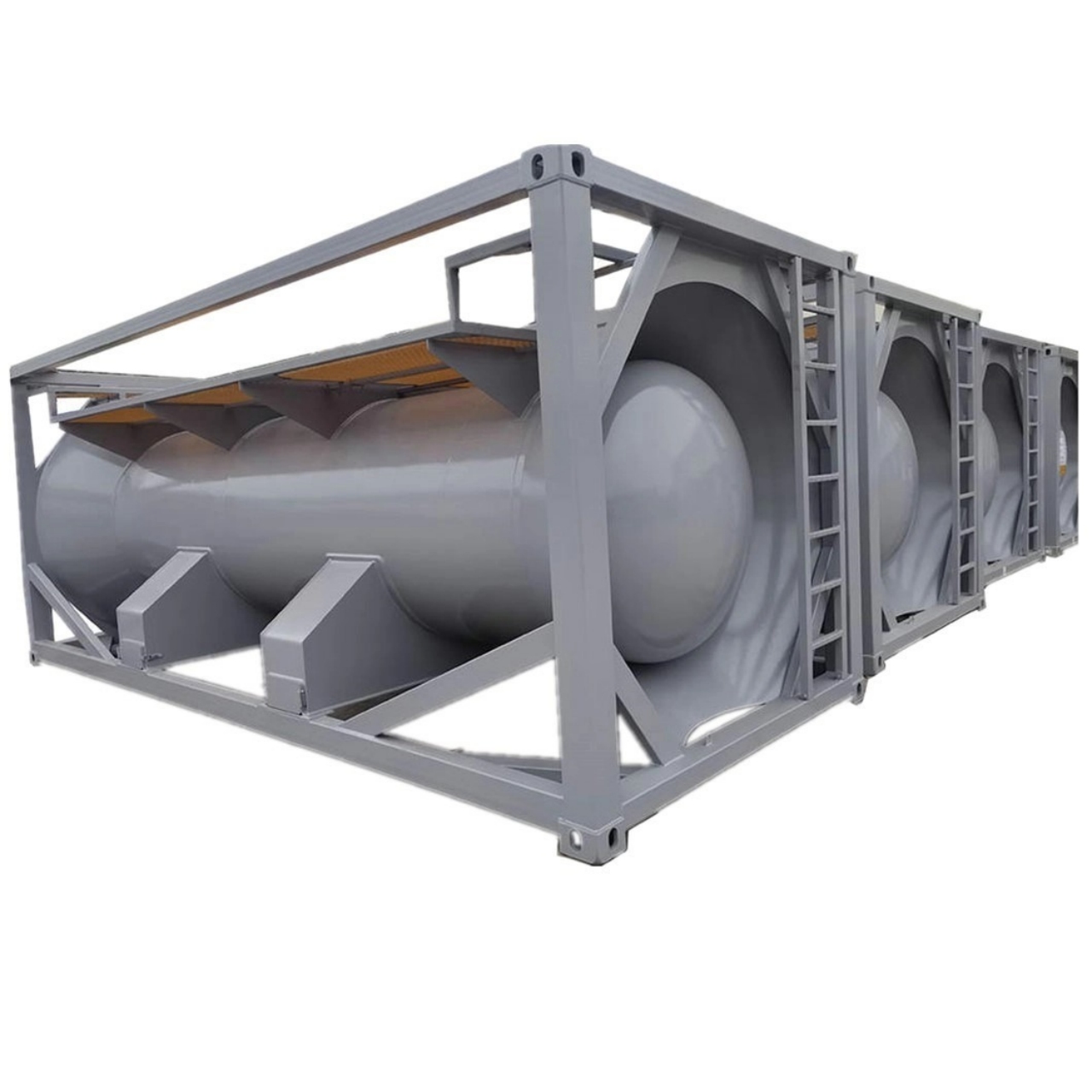

ISO tank containers, or simply ISO tanks, are cylindrical pressure vessels built within a standardized steel frame. The “ISO” refers to the International Organization for Standardization, which prescribes the dimensions and requirements for containers used in international freight to ensure compatibility across different transport modes. A standard ISO tank measures 20 feet in length, 8 feet in width, and 8.5 feet in height, conforming to the ISO 668 standard for intermodal containers.

These tanks are made from high-grade stainless steel, often lined with protective materials to resist corrosion, depending on the type of cargo they carry. The structure is housed within a protective steel frame, allowing the tank to be handled like any standard container using cranes, forklifts, or spreader bars, and stacked in port and rail terminals.

Types of ISO Tank Containers

ISO tanks come in various configurations, depending on the cargo requirements:

- Standard Liquid ISO Tanks: For non-hazardous and hazardous liquids like alcohol, oils, and chemicals.

- Gas ISO Tanks: Designed to carry compressed gases such as LPG (liquefied petroleum gas), LNG (liquefied natural gas), ammonia, or butadiene.

- Refrigerated or Heated Tanks: Equipped with temperature control for food-grade liquids or temperature-sensitive chemicals.

- Swap Body Tanks: With a larger capacity than standard ISO tanks, mostly used in Europe and restricted to road and rail.

- Cryogenic Tanks: For ultra-cold liquefied gases like liquid nitrogen or oxygen, with vacuum-insulated double-wall construction.

Each tank is tailored to meet the requirements of its specific cargo in terms of pressure, temperature, chemical compatibility, and safety regulations.

Intermodal Capabilities and Global Reach

The intermodal design of ISO tank containers is one of their defining advantages. They can be loaded at a manufacturing facility, transported by truck to a rail terminal, moved by train to a port, loaded onto a container ship, and delivered to an inland destination with minimal handling of the cargo itself. This reduces the risk of contamination, spillage, or evaporation during transit and lowers the cost and complexity of the logistics chain.

This intermodal versatility is especially valuable for cross-continental trade. For instance, an ISO tank loaded with liquid chemicals in Germany can be shipped by rail to Rotterdam, transported by sea to Shanghai, and then trucked to a manufacturing plant in inland China—all without the cargo being decanted or repackaged.

Safety and Regulatory Compliance

ISO tank containers are engineered to meet stringent safety standards set by bodies such as the International Maritime Organization (IMO), the International Tank Container Organization (ITCO), and the United Nations Recommendations on the Transport of Dangerous Goods. Tanks must comply with IMDG (International Maritime Dangerous Goods) code, ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road), and RID (Regulations concerning the International Carriage of Dangerous Goods by Rail), among others.

Safety features include pressure relief valves, manifolds, vapor return systems, grounding points to prevent static buildup, and insulation or cladding to maintain internal temperature. Before being certified for use, each tank must undergo hydrostatic testing, leak testing, and rigorous inspections to ensure structural integrity. Maintenance intervals are also strictly scheduled—usually every 2.5 years and 5 years for in-depth testing.

Environmental and Economic Advantages

ISO tank containers offer significant environmental benefits. Compared to traditional drum or IBC (Intermediate Bulk Container) transport, ISO tanks reduce the amount of packaging waste and improve payload efficiency. A single ISO tank can carry up to 26,000 liters of liquid cargo—equivalent to more than 1,000 standard 25-liter drums—making them more space- and cost-efficient.

Their reuse and long service life—often 20 to 30 years—further reduce the carbon footprint of bulk transport. Many operators also refurbish and recondition ISO tanks, extending their usability while maintaining performance and safety.

From a financial standpoint, ISO tanks lower transportation and handling costs, reduce product loss, and increase delivery reliability. The ability to use one container across multiple transport modes reduces labor, handling, and infrastructure needs.

Applications Across Industries

The versatility of ISO tank containers has made them indispensable in a wide array of sectors:

- Chemical Industry: Transporting bulk chemicals, including acids, solvents, resins, and hazardous materials.

- Oil and Gas: Moving liquefied petroleum gases (LPG), LNG, and refined fuels.

- Food and Beverage: Carrying food-grade liquids such as wine, fruit juice, edible oils, and milk in tanks with sanitary linings.

- Pharmaceuticals: Moving temperature-sensitive medical liquids with insulated and temperature-controlled tanks.

- Industrial Gases: Delivering high-pressure or cryogenic gases in specialized ISO tank designs.

ISO tanks also support emergency response and humanitarian logistics, such as delivering potable water, chemicals, or fuels in disaster zones.

Technological Advancements

Modern ISO tank containers are increasingly integrated with smart technologies. GPS tracking, pressure and temperature sensors, and real-time cargo monitoring systems are becoming standard features. These technologies allow shippers and logistics providers to monitor the condition and location of the cargo throughout the supply chain, enhancing transparency, security, and proactive risk management.

Some tanks are equipped with remote valve control and automated safety mechanisms that improve handling precision and reduce human error during loading and unloading operations.

Future Outlook

With global trade continuing to expand and sustainability becoming a central concern, ISO tank containers are set to play an even larger role in the future of liquid and gas logistics. Innovations in tank design, materials, and IoT integration will enhance their efficiency and environmental performance. At the same time, growing demand for reliable and safe transport of chemicals, fuels, and food-grade liquids will continue to drive the need for ISO tank container fleets across continents.

In conclusion, intermodal ISO tank containers represent one of the most reliable, efficient, and sustainable solutions for global liquid and gas transport. Their robust construction, intermodal compatibility, and high safety standards make them the preferred choice for industries that demand both operational efficiency and uncompromising quality. As the world moves toward more resilient and eco-friendly supply chains, ISO tanks are not just a transport option—they are a strategic asset in global logistics.