Dust Material Transport Trucks, also known as powder tankers, are mainly used to transport dry powder materials with particle diameters no greater than 0.1mm, such as cement, fly ash, lime powder, etc.

In the early days of the cement transport market, gravity-discharge trucks were the first to appear. These vehicles functioned much like modern tipper trucks with covered tops. During unloading, the cargo box would be lifted, allowing materials to be discharged by gravity. However, the downside of this method was that materials could only be unloaded to positions lower than the truck’s cargo bed.

By the 1950s, the cement transport market saw a new development: Trucks equipped with onboard screw conveyors for unloading. However, this method often caused damage to the screw unloader, making it far from an ideal solution.

It wasn’t until the 1960s that pneumatic discharge tankers emerged, offering a much more practical solution for unloading powdered materials.

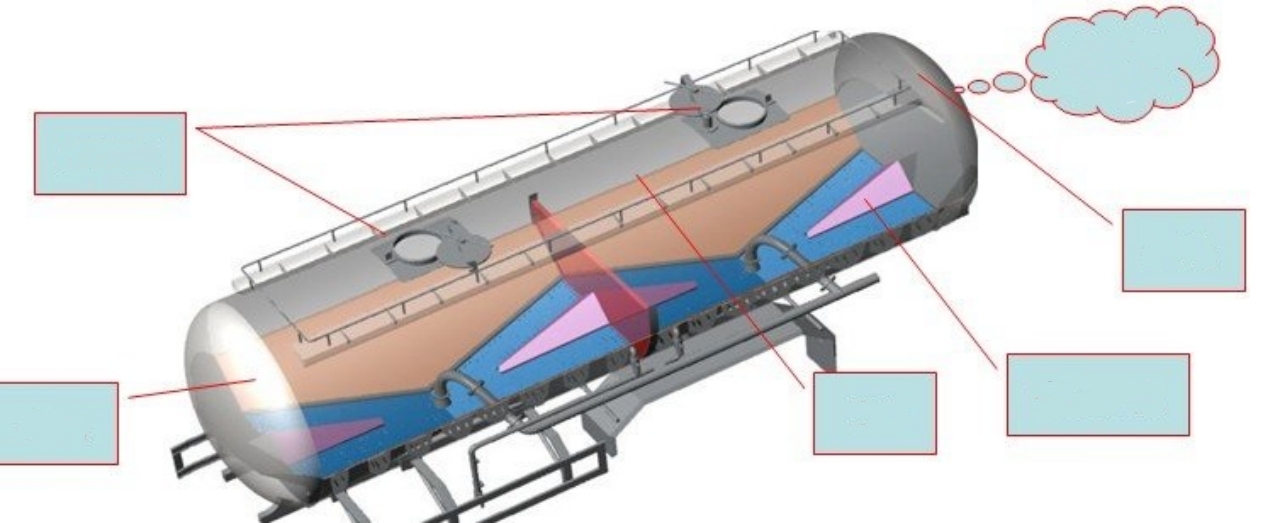

This unloading method uses an air compressor powered by a diesel engine. The compressed air is delivered through intake pipelines into the tank, where a fluidizing device increases the flowability of the powder, making it behave more like a liquid. The powder can then flow over a fluidized bed with a certain slope.

Due to the pressure difference between the inside and outside of the tank, when the discharge valve is opened, the powdered material is pushed along the discharge pipeline to the designated location along with the airflow.

▎Modern Powder Tankers Make Cement Transport Easier, Faster, and More Efficient

The Dry Bulk Trailer introduced today is manufactured by CSCTRUCK China Tank Truck, with a tank volume of 27.5 m³.

Because its load capacity is relatively low, the air compressor is powered directly via a PTO (power take-off) connected to the transmission. This truck uses a Bohai HYCW-12/2 air compressor, which has a rated power of 38 kW, an air delivery rate of 12 m³/min, and an operating speed of 1,000 rpm.

Bohai air compressors are widely used in powder tankers. According to feedback from past customers, this compressor has decent quality and a good reputation.

On the left side of the tank, there is a water tank device that can be used to spray water on the brakes during long downhill descents.

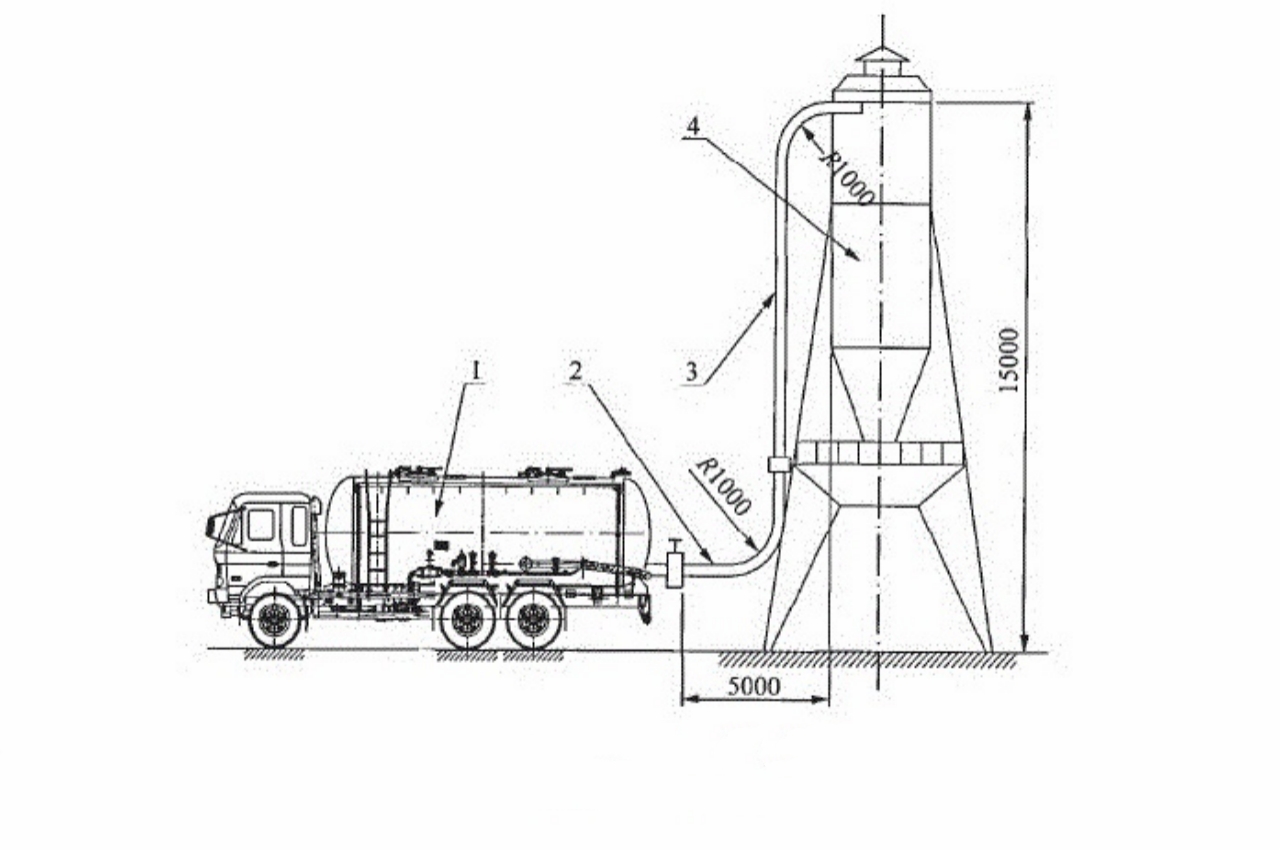

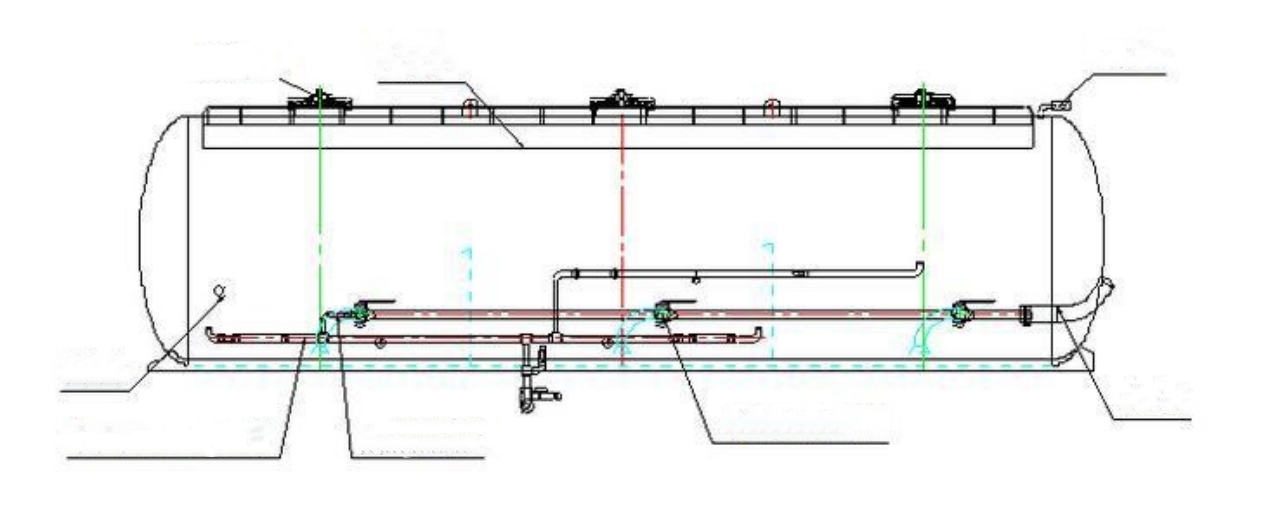

Looking at the rear of the vehicle, the material discharge and air outlet pipes are fixed below the tank body. The truck is fitted with 12R22.5 steel radial tires. During unloading, the powder can be transported horizontally up to 5 meters and vertically up to 15 meters.

On the vehicle’s left side is the trailer pipeline system. The air outlet pipe from the compressor is connected to the front and rear air inlets of the tank compartments, delivering compressed air into the tank. A secondary air assist pipe, controlled by a secondary air valve and connected to the discharge pipe, provides additional air support during unloading to enhance efficiency.

The emergence of dry bulk trailers has effectively solved the problems associated with cement transport. Because cement is now transported in tanks instead of paper bags, it eliminates the need for manual bagging, reduces labor, increases productivity, and lowers the use of packaging materials, thus cutting transportation costs.

Additionally, this method solves the issue of bulk cement being prone to moisture. With tank transport, cement can be stored inside for up to a year without deterioration. However, powder tankers are only suitable for transporting large quantities of cement, such as for concrete batching plants. For users with lower cement consumption, conventional bagged packaging is still necessary.